Together with:

Greetings from foggy Maine! Each summer I spend a few weeks on the coast of Maine with my family to enjoy “Vacationland” with some boating, fishing and eating. This summer, the weather has been pretty bad, and right now, I can’t see beyond 100 feet. Alas, it’s given me some time to focus on Swaylocks.

Before some updates from our intrepid sponsors, a little teaser on some of the changes coming down the pike for Swaylocks. For the last several months, I’ve been working with a developer to migrate the original Swaylocks forums onto the Discourse platform. Not Discord…Discourse.

Discourse is one of the finest, most widely used, open source forum platforms today. It’s much closer in style and function to the old Swaylocks forums (or I should say the most recent old Swaylocks forums), with a ton of newer features I could never conjure on the old platform.

I’m migrating all posts, images, users, usernames and emails. If all goes well, diehard veterans and newer users alike should be able to resume discussion in this new forum where they left off. 🤞

Beyond that, my plan is to wrap all of the disparate sections of Swaylocks (forums, video on-demand, newsletter, swag shop, etc) under one roof in the hope of making the Sways experience more unified.

One thing I’m still undecided on is the name, so I guess it’s time for poll:

A message from Greg Loehr…

Resin Research Bio Based Systems

Resin Research’s involvement in environment dates back to an environmental study on surfboard building done in conjunction with Florida Tech University in the 1988. The results of that study mostly focused on reduced waste and worker safety. Our results were focused on six aspects and below are the results:

- Better worker safety - Achieved by the use of better gloves, face masks, goggles and thorough the elimination of acetone and VOC based resins (polyester).

- Minimizing material waste - The study began with the weighing of traditional resin use, acetone use, blanks, fiberglass and all other materials from fins to leash plugs to sandpaper etc. We then concentrated on ways to reduce or eliminate waste.

- Reduction or elimination of toxic VOC chemicals - We switched from polyester resin to epoxies. This reduced vapor of the resin used by 98% and since we also reduced resin use by 70% the final number was far below 1%. We also eliminated 100% of acetone by using scrap fiberglass and water based hand cleaner for clean up. This also added to worker safety.

- Lowering emissions - As stated just above over 99% of VOC’s were eliminated by changing resin and elimination of 100% of acetone emissions.

- Recycling - Recycling of all foam scraps were recycled, sent back to the foam manufacturer. The manufacturer agreed to take back the scrap and they began a “Regrind” program which reuses 100% of the foam they get back which is made into insulation material.

- Reuse of materials - While little things like making scrap glass a clean up material and recycling foam for reuse may seen minor, at the end of the day they added to our weight totals significantly.

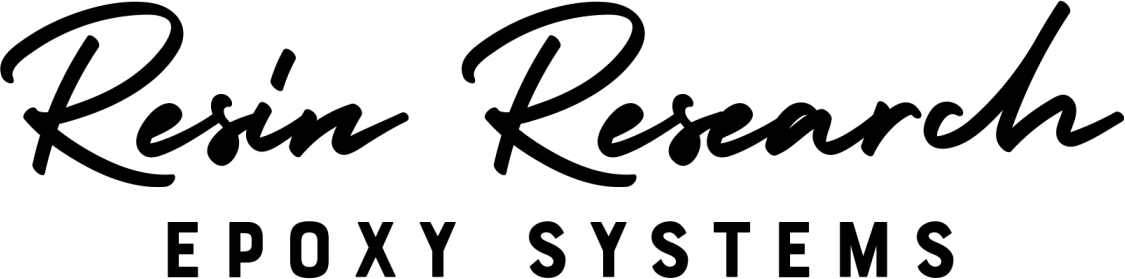

Comparisons (Main Components)

We reduced or eliminated nearly all of the waste over traditional board building practices. We found that waste tripled the amount of material needed and thereby increased costs of production dramatically. It also reduced emissions and left us with a much cleaner, safer shop. It’s funny but one of the greatest aspects to me was when the city’s waste management came by and picked up our $80 a month dumpster. After that we just had a trash can which was picked up once a week for free. We were buying extra materials so the city could charge us to take it away. An update of this study was published in 1999 by Surfer Magazine (“Surfing’s Dirty Little Secret”) and again in Longboarder magazine and was, rightly, highly scrutinized. Our facts were clearly stated for those willing to listen.

In 1994 the United Nations headed up a sustainability round table in Oslo. Their conclusions mirrored ours very closely with two additions. They added:

- The use of renewable energy sources

- The use of bio based chemistry where applicable

We agree!

1/2 of our Tucson, AZ plant solar array

Bio Based Epoxy Resins are the latest technology outlined by the UN. These new products offer a lower eco footprint (1/2 of bio content) and can offer a somewhat lower toxicity. The downside today is that they do come at a premium price and they lack the top shelf cosmetics (color) of their standard counterparts. But structurally and their “factory in use” quality are equal.

Today all of the standard RR resins have Bio content of 25-28%. This is not our!"Bio Science” line, this is just our standard stuff. Just a couple years ago these numbers would have been “Bio Science” cutting edge.

Obviously it should be noted that this tech is still emerging and improvements are certainly forthcoming. The velocity of change we see in a year now is equal to the improvements we used to see in 5 - 10 years. Our 2023 line has just been released and we’re already beginning work on its successor. Stay tuned!

In our “Bio Science” line of products this bio content runs 35 - 55% on the resin side alone. Mixed totals with hardener run from 30 - 39% depending on which product you’re using.

The future of these new materials is evolving rapidly. Stay tuned.

Greg

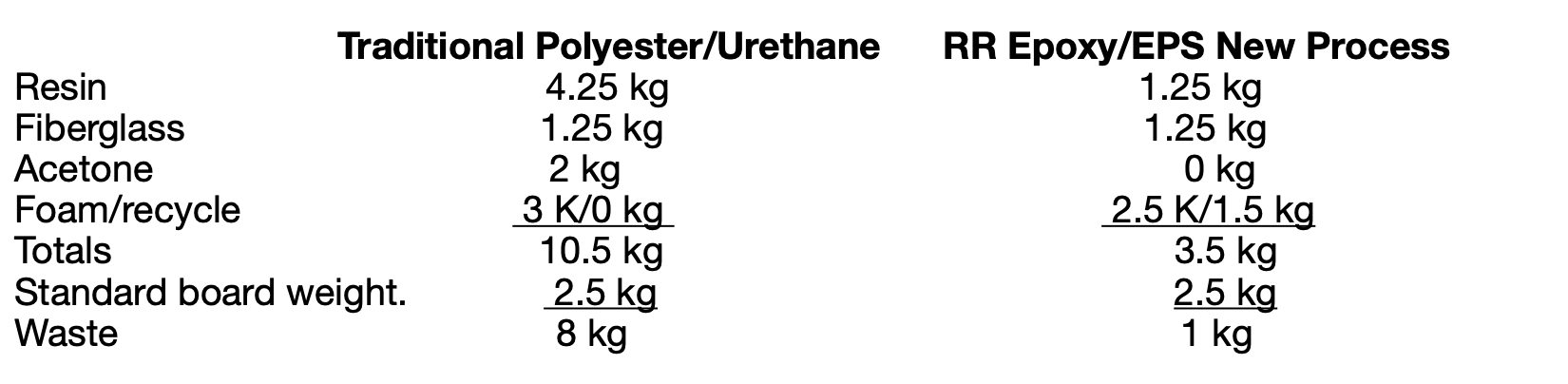

CNC Machines

Did you know that besides producing the industry leading surfboard shaping software, and a CNC machine of their own design, AkuShaper also sells used CNC machines?

Be sure to check out their site for listings, subscribe to their newsletter or contact them on the Sways Discord Forums or from their website if you are in the hunt for one or have one to sell.

Right now, they have a 15’ Kedis Pro, brand new in Sao Paulo, Brazil.

Bing Copeland to be Honored as ICON of FOAM

at the 2023 Board Room

Eight shapers gear up for friendly yet intense competition.

June, 2023, Del Mar, Ca. — The Boardroom International Surfboard Show presented by US Blanks is honoring legendary surfboard builder Bing Copeland in the Icons of Foam Shape-off competition. The Boardroom Show is widely recognized as the world’s largest surfboard marketplace, and takes place October 7 & 8, 2023, in beautiful Del Mar, Ca. Established in 2007, 2023 marks the Boardroom’s 16th year and its 21st show.

“I’m looking forward to being the Icon of Foam honoree,” said Bing Copeland. “To have a few of the current young shapers compete to duplicate several of my most popular models from the 60’s & early 70’s will be a fun challenge to watch. It’ll be fun judging the competition with Matt Calvani”.

“We are humbled and ecstatic to honor Bing Copeland at this years’ show,” said Boardroom Show Executive Director Scott Bass. “Bing’s legacy in the surfboard manufacturing industry is lengthy, storied, and transcendent. But as great a surfboard builder as he is (he’s among the greatest ever) Bing Copeland is an exceptional human being.”

Bing Copeland opened his first surf shop in the fall of 1959 with his friend Rick Stoner and became one of the major surfboard builders of the sixties and early seventy’s. The business grew at an exponential rate, and Bing expanded his factory to include a glassing area and a team of first-rate shapers such as Dick Brewer, Dick Mobley, Mike Eaton, Dan Bendiksen, John Mobley, Wayne Land, and George Lanning.

The late sixties was the beginning of the end for the major manufacturers. It was a time of the “back yard board” and “no label” surfboards. Copeland, along with his master shapers and new designers, the Campbell Brothers, transitioned to shorter boards. The hand-off of the BING Surfboards label to shaper Matt Calvani occurred in 2000 and BING continues to produce incredible surfboards with Copeland’s watchful eye and decades of insight lighting the path.

Eight international shapers will honor Bing Copeland and compete for the $2K first prize and their name etched into the Mike Marshall Perpetual Trophy (see the trophy at Hansens Surf Shop in Encinitas).

Copeland chose shapers Thomas Bexon (Australia), Hank Warner (San Diego), Roger Hinds (Seal Beach), Wayne Rich (Goleta), Michael Arenal (Ventura), Dane Perlee (San Diego). Those six heavy hitters join defending champion Rick Rock (San Clemente) and East Coast Surf Expo shape-off winner Josh Peterson (East Coast/Hawaii).

The Boardroom Show’s Best In Show board build-off competition features The Bonzer. It was 50 years ago, in 1973, that two forward-thinking, creative brothers from Oxnard, Ca., Malcolm and Duncan Campbell, licensed their groundbreaking Bonzer design to Bing Copeland and Bing Surfboards.

The Boardroom’s Best In Show board build-off is free to enter and open to any board builder worldwide. Malcolm and Duncan Campbell will be judging based on creativity, functionality, and construction. Past winners of Best In Show include Ryan Sakal, Renny Yater, Pat Rawson, Gary Linden, Dane Hantz, Stu Kenson, Donald Brink, John Simon, Barry Snyder and many others.

The Boardroom International Surfboard Show presented by US Blanks takes place October 7 & 8, 2023 at the Del Mar Fairgrounds Exhibition Hall.

Learn more about exhibiting your boards, gear, art or wares at the largest surfboard marketplace in the world.

Swaylocks is brought to you by our generous sponsors & partners:

Thanks for reading and until next time, enjoy & keep building with stoke,

Mike 🤙